- Clean room doors and windows

- Cleanroom Door Options

- Airlocks & Interlocks

- Clean Room Door & Window

- Clean Room Door & Window

- Clean room doors

- Hinged Doors

- Sliding Doors

- Features

- Completely flat surface

- Easy to integrate

- Thick door panels

- High level of airtightness

- Resistance to cleaning products

- Safety glazing

- Antistatic surfaces

- Premium hardware

- Options

- Card opening

- Mechanical locking

- Electronic lock system

- Stainless steel door panel inserts

- Automatic door operation

- Mineral wool fillings

- Open without a handle

- Featured Products

- Clean room doors

- Clean room pass boxes

- Get to know Kleanlabs competitive prices! Ask for inquiry

- Clean room Doors

- Turning door basic

- Fire-resistant turning door

- Sliding doors

- X-rays door

Clean room doors and windows

Cleanroom Doors

Mecart offers several clean room door and window options, ranging from our famous Teardrop Shape Window to the conventional rectangular rounded-corner-shape. Our specialists can help you determine which type of doors and windows will best suit your purpose.

Request a quote

Cleanroom Door Options

Mecart-made clean room doors can be configured as single or double swing doors (manual or motorized) and can be 100% customized. Sliding doors and high speed rollup doors are also available. All doors are airtight, easy to clean with smooth surfaces as well as corrosion resistant.

Doors are important in cleanroom design. Their role is not limited to the access of personnel and merchandise. Door vision panels are important to see obstacles, for supervising personal, monitoring processes and maximising natural light.

Airlocks & Interlocks

To maintain cleanroom pressure differentials, passage should be through airlocks (and ideally controlled by interlocks). Airlocks are mostly used for the coming and going of personnel in gowning and degowning areas and material transfer airlocks. Our wall panel and door system can easily be configured with an interlock system, with two subsequent sets of doors, each opening separately with airspace between them. Interlocks prevent potential particle migration between two clean rooms which happens when two doors are accidentally opened at the same time.

Clean Room Door & Window

Our company’s cleanroom door panelsinclude metal door (aluminum frame plus PCGI door), steel door (steel frame PCGI door) and HPL door (HPL sandwich panel and aluminum or steel frame). According to the switch mode of the door, it can be divided into pull/push door and sliding door.

Our clean room sliding doorare compatible with any level of clean room and can be customized to your needs. We use high quality steel to make the door and double seal on all sides to prevent leakage and contamination. We offer features such as custom sizes and colors, electronic locks and cleaning strips.

In order to form a complete set for all levels of clean room, purification room, dust-free room, trailer and other places uses color plate partition. Around double sealing, thermal insulation, heat insulation, sound insulation. Color plate or stainless steel plate can be used to customize different size of clean door, locks, color of color steel, door strip and etc, all of which can be configured in accordance with the requirements.

Wonzon is one of the leading clean room doors manufacturersin China, feel free to contact us.

Clean Room Door & Window

Our company’s cleanroom door panelsinclude metal door (aluminum frame plus PCGI door), steel door (steel frame PCGI door) and HPL door (HPL sandwich panel and aluminum or steel frame). According to the switch mode of the door, it can be divided into pull/push door and sliding door.

Our clean room sliding doorare compatible with any level of clean room and can be customized to your needs. We use high quality steel to make the door and double seal on all sides to prevent leakage and contamination. We offer features such as custom sizes and colors, electronic locks and cleaning strips.

In order to form a complete set for all levels of clean room, purification room, dust-free room, trailer and other places uses color plate partition. Around double sealing, thermal insulation, heat insulation, sound insulation. Color plate or stainless steel plate can be used to customize different size of clean door, locks, color of color steel, door strip and etc, all of which can be configured in accordance with the requirements.

Wonzon is one of the leading clean room doors manufacturersin China, feel free to contact us.

Clean room doors

Hinged Doors

This KleanLabs door is the perfect addition to any cleanroom, as it is system independent and easy to mount. It is high-quality and yet is pleasing to the eye. We recommend the TT-1 model specifically to be used in laboratory and cleanroom environments.

This KleanLabs door is the perfect addition to any cleanroom, as it is system independent and easy to mount. It is high-quality and yet is pleasing to the eye. We recommend the TT-2 model specifically to be used in laboratory and cleanroom environments where a wider accessibility is needed.

Sliding Doors

This KleanLabs door is based on an easy-to-open sliding door system, that is compliant with cleanroom standards, and is system independent. We recommend this high-quality door to be used in cleanroom environment with larger openings enabling trucks and trolleys to pass.

Features

Completely flat surface

We designed our doors to have completely flat surfaces on both sides. This makes our doors exceptionally easy to clean and maintain. There are no edges for any dust to settle in, even the built in windows are smoothly embedded. Our doors are also completely flush with the clean room walls, if the walls are 60 mm thick.

Easy to integrate

Our doors are completely system independent. Many clean room builders will produce doors that are compatible only with their own design. KleanLabs doors however can be installed to any clean room. We designed the bezels so they fit any wall structure.

Thick door panels

In order to provide strong and reliable quality, KleanLabs doors are reinforced. With their 60 mm thickness, these clean room doors have outstandingly high resistance to bending. Their aluminium built will increase their durability and long-lasting functionality.

High level of airtightness

KleanLabs doors offer the most appropriate level of airtightness your cleanroom is ever in the need of. Measured at 200 Pa pressure, they offer a 3,5 m3 / hm2 airtightness. Our doors are also equipped with a double gasket technology and have an integrated sink gasket.

Resistance to cleaning products

It is remarkably easy to maintain our doors. According to tests we have carried out, they are entirely resistant to any popular cleaning product. There is no chemical interaction between the material of KleanLabs door panels’ and any sort of detergent.

Safety glazing

Security is of paramount importance to us, therefore every detail of our products is thought through with great care. We equip shatter proof, safety glazing in the windows of KleanLabs doors. This means, should the window break in, the glass will not scatter, but stay in place.

Antistatic surfaces

To keep your cleanrooms truly hygienic, all of the materials we are working with are antistatic. This means they are not attracting any occurring contamination. Furthermore, dirt or micro contaminants are also not going to show up on our products.

Premium hardware

Our philosophy is that great craftsmanship stars with high-quality materials. We exclusively work with the best, industry-leading suppliers. Therefore, every little element in our products, be them locks, hinges or door pullers, are made of the best quality metals.

Options

Card opening

Our doors can be equipped with an integrated access control system to fit your corporate environment. Set a hierarchy to cards, and give different authorities to your employees.

Mechanical locking

Close and open your cleanrooms with keys. For maximum safety, and prioritized entrance, we offer custom and master keys as well.

Electronic lock system

For enhanced security, choose the electronic interlock pin for sluice system, with an emergency opening button and indicator lights. Automatic doors with interlocking control and blocking. Install master and slave doors for prioritized entrance.

Stainless steel door panel inserts

Our doors come with powdered aluminum door panel inserts by default. Upon special request however we are able to offer stainless steel inserts. Door frames are made of aluminium in every case.

Automatic door operation

Doors can open at the touch of a button, and then close automatically. The system detects passage and closes only when it is safe. It also upholds all safety requirement. The system is driven by a quiet, hidden motor.

Mineral wool fillings

Our door panels come with PIR foam fillings by default. For an enhanced insulation performance, we offer mineral wool fillings too.

Open without a handle

For an even easier and smoother entrance, our doors can open in case of movement, automatically, with a magic switch, or with hand movement recognition.

Featured Products

Clean room doors

Clean room pass boxes

Get to know Kleanlabs competitive prices!

Ask for inquiry

Kleanlabs.com © Copyright 2021 |

Our website uses cookies. For further information, click here

- Privacy Overview

- Mandatory cookies

This website uses cookies to make the website work properly and to provide the best user experience for visitors to the site. The information stored in the cookies is stored in the browser of visitors to the website and contains information that can help you to find out if you are returning to the website or helping the most frequently visited pages of the website, the most interesting ones, which parts are best used .

The user can adjust the cookie settings in detail through the tabs on the left.

Cookies that are absolutely necessary must be enabled at all times to save the settings for further handling of cookies.

If this cookie is not enabled, we will not be able to save the selected settings, which will cause you to re-enable cookies for each visit.

Clean room Doors

Turning door basic

The metal swing door is one of the main elements of clean rooms and workplaces with maximum safety, sterility and sanitization. The body of the door is formed by a shaped cassette made by precision molding. Along the perimeter of the body there are stiffeners to increase the rigidity of the door’s portal, as well as to fasten the hinges and the lock. The body, the stiffeners and the filler are mutually glued under pressure.

The door can be either solid or glazed, with a double glazing. The glass sheets are flush with the surface of the door. The space between the panes can be equipped with a curtain.

- The body of the door and the doorway are cleaned and disinfected with ordinary detergents, depending on the finishing layer

- The glazing of the doors is cleaned with ordinary detergents for glass. Do not use acids, solvents or similar chemicals.

- Grease steel hinges, and, if necessary, adjust the hinges (every two months)

- Check the door closer every two months or, if necessary, adjust using the screws

- Cleenroom doors with a sealing strip on the bottom: the area in front of the door must be kept clean without solids, which could cause seizure or damage to the sealing strip

- The use of steel doors in RAL version in rooms with a relative humidity of more than 60% is not allowed to ensure a permanent quality of the surface finish.

Fire-resistant turning door

A fireproof metal swinging door, supplied with a metal frame, is one of the main elements for clean rooms and workplaces with the requirement for protection from fire while maintaining maximum sterility and simple maintenance. The single-leaf door is equipped with a fireproof lock and a handle with a fireproof finishing. The passive leaf is provided with a lower and upper slide in the case of a double-leaf door.

The door leaf can be a solid or glazed, which is a double glazing. The outer surfaces of the glass are flush with the surface of the door. The intermediate space is equipped with a safety fireproof glass.

Care and maintenance

- The bode of the door and the doorway are cleaned and disinfected with ordinary detergents, depending on the surface finishing

- Glazing of doors

— cleaned with ordinary detergents for glass

— do not use acids, solvents and similar chemicals - Steel door hinges

— grease and, if necessary, adjust the hinges (every two months) - Door closer

— adjust its speed and closing force using screws every two months or if necessary - Doors with a sealing strip on the bottom

— the area in front of the door must be kept clean without solids, which could cause seizure or damage to the sealing strip

— the use of steel doors in RAL version in rooms with a relative humidity of more than 60% is not allowed to ensure a permanent quality of the surface finish

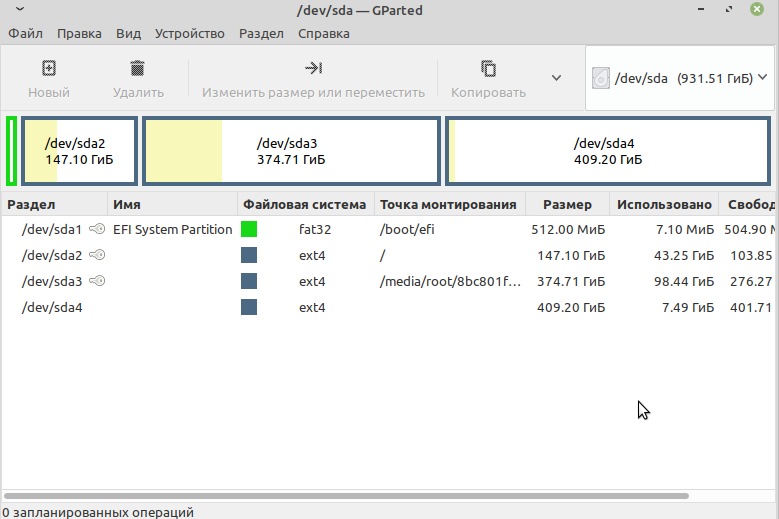

Sliding doors

The sliding door provides a wild spectrum of door types described by basic and additional parameters that enable to produce the door on the customer’s requirements. This is produced as onewing or double-wing door.

Automatic sliding doors are a. c. motor powered. Motor is operated by frequency converter which is controlled by microprocessor and that control automatic door faultlessly in each situation with emphasis on safety. It is possible to control the sliding door by means of control accessories, including remote control and possibility of connection to safety system.

The door wing is either full or glazed by the PHARMA system, which is a both sided glazing where glass plate is fl ush with the door wing surface. The space between the glass plates may be provided with sun-blinds.

- coat of optional material and surface treatment

- fill — mineral wool

- optional glazing and glazing dimensions

- fittings, lock

- elbow switch

- proximity switch

- contact switch

- microwave radar

- switch knob

- card scanner

Partition thickness for sliding door installation

- 60, 80, 100, 120 mm

- another thick.- it is possible to produce the door as atypical

X-rays door

The metal X-ray-resistant door with the metal frame is one of the main elements for X-ray protection of clean rooms. Doors have a sandwich construction. The case of the door leaf is formed by a shaped cassette made by precision molding. Along the perimeter of the body there are stiffeners to increase the stiffness of the door leaf, as well as to fasten the hinges and the lock. The standard cavity filler is mineral wool with an additional HPS plate and a shielding lead insert. A thickness of 0.4 mm to 3 mm. As a part of the door there is a shielded joint with protection from X-rays.

When the door leaf is opened on 180º, the width of the passage is equal to the width of the jamb in the light.

The thickness of the shielding lead-in liner is always determined by the designer based on radiation limits in accordance with the legal norm.

Care and maintenance:

- The case of the door leaf and the doorway are cleaned and disinfected with ordinary detergents, depending on the finishing of the surface

- Door closer

— adjust its speed and closing force using screws every two months or if necessary

- Door with sealing strip

— the area in front of the door must be kept clean without solids, which could cause seizure or damage to the sealing strip.

- The use of steel doors in RAL version in rooms with relative air humidity exceeding 60% is not allowed to ensure a permanent quality of the surface finish.