- Grbl controller linux deb

- Latest commit

- Git stats

- Files

- readme.md

- About

- Grbl Controller

- Contents

- Overview

- Home page

- On-line Documentation

- Downloading

- Building from Code (may be necessary for Linux)

- Using Grbl Controller 3.0

- Grbl controller linux deb

- Latest commit

- Git stats

- Files

- readme.md

- About

- Grbl controller linux deb

- About

- Grbl controller linux deb

- This release includes a critical bug fix (rare) and some other minor bug fixes, updates and new non-critical features.

Grbl controller linux deb

GRBL controller application with G-Code visualizer written in Qt.

This branch is not ahead of the upstream master.

No new commits yet. Enjoy your day!

Latest commit

Git stats

Files

Failed to load latest commit information.

readme.md

GRBL controller application with G-Code visualizer written in Qt.

- Controlling GRBL-based cnc-machine via console commands, buttons on form, numpad.

- Monitoring cnc-machine state.

- Loading, editing, saving and sending of G-code files to cnc-machine.

- Visualizing G-code files.

Version 0.8 release:

- You can save files, transformed according to heightmap.

- Console window have adjustable size now.

- Added «Degree» minimum arc size to parser settings.

- Some minor bugs fixed.

Qt 5.4.2 with MinGW 4.9.1 compiler

Version 0.7 release:

- Drag & Drop mechanism support added. You can drop files & plain text to main program window to open them.

- «Abort» button added. File transfer can be interrupted without loss of work coordinates offsets now.

- M2, M30, M18, M19 commands support added.

- French translation added.

- Some bugs fixed.

Version 0.6 release:

- Improved visualizer performance.

- Some appearance settings added.

Version 0.5 release:

- Toolpath highlighting on g-code program table selection.

Version 0.4 release:

G-code modification with heightmap.

Original file:

Heightmap:

Bicubic interpolation:

Modified file:

Version 0.3 release:

- Recent files & commands lists added.

- Custom Z-probe commands supported now.

- Imperial units of GRBL reports support added.

- Main form compacted.

Visualizer only view:

Table only view:

Live G-code editing:

Version 0.2 release:

- Jog/spindle control with numpad added:

- Feed override function added.

- «Spindle», «Feed», «Jog» groupboxes collapsible now.

- Visualizer works in «Check mode» now.

- Visualizer Z-buffer option added.

- Some bugs fixed.

Support the «grblControl» project. If you’d like to donate, all proceeds will be used to help fund supporting hardware and testing equipment. Thank you.

About

GRBL controller application with G-Code visualizer written in Qt.

Источник

Grbl Controller

Contents

Overview

Grbl Controller is a piece of software which is used to send GCode to CNC Machines, such as a ShapeOko. As of version 3.0, the software has been optimized to send GCode to a Grbl Arduino Shield, which is the standard and default controller type for the ShapeOko.

Grbl Controller is written to work on Windows, Mac, and Linux. It has been written as a superior replacement for the popular GCodeSender, and UniversalGCodeSender.

User Bobt was able to get it running on a Raspberry PI.[1] c.f. Running Grbl Controller on Raspberry Pi

Implements “Agressive preload” and Z-rate limiting options.[2]

Will trim too-long lines when sending.[3] Current version doesn’t consider line-endings, so will overflow the buffer, change the Grbl Line Buffer Size in Tools | Options from 50 to 49 (48 on linefeed and carriage return systems such as Windows).[4]

Home page

On-line Documentation

Downloading

Installers for Mac, Windows and Linux Grbl Controller by Zapmaker

Building from Code (may be necessary for Linux)

Using Grbl Controller 3.0

- Power up Arduino and shield

- With motor off, manually position milling bit over origin (0,0) on the work piece. The origin is the intersection of X and Y on your CAD drawing.

- Start Grbl Controller

- Select COM port and open

- Choose appropriate step size (start with 1)

- Press the Z down button, the milling bit should move down towards the work piece 1 mm. The Z jog speed can be adjusted in menu Tools -> Options

- Repeat until the the bit is almost touching

- Turn on motor

- Press Grbl Controller’s Reset button to zero the Arduino Grbl code

- Choose Send GCode radio button

- Open desired file, usually .nc

- Press Begin. If for some reason there is a long, slow traverse, the controller may time out. Increase timeout value in Tools -> Options

- Turn off motor when milling is complete

- Press the Reset, Stop or Close button on Grbl Controller — the steppers should stop within a second or two. If not, power off your shield

Источник

Grbl controller linux deb

GRBL controller application with G-Code visualizer written in Qt.

This branch is not ahead of the upstream master.

No new commits yet. Enjoy your day!

Latest commit

Git stats

Files

Failed to load latest commit information.

readme.md

GRBL controller application with G-Code visualizer written in Qt.

- Controlling GRBL-based cnc-machine via console commands, buttons on form, numpad.

- Monitoring cnc-machine state.

- Loading, editing, saving and sending of G-code files to cnc-machine.

- Visualizing G-code files.

Version 0.8 release:

- You can save files, transformed according to heightmap.

- Console window have adjustable size now.

- Added «Degree» minimum arc size to parser settings.

- Some minor bugs fixed.

Translations will be available from here: translations

Version 0.7 release:

- Drag & Drop mechanism support added. You can drop files & plain text to main program window to open them.

- «Abort» button added. File transfer can be interrupted without loss of work coordinates offsets now.

- M2, M30, M18, M19 commands support added.

- French translation added.

- Some bugs fixed.

Version 0.6 release:

- Improved visualizer performance.

- Some appearance settings added.

Version 0.5 release:

- Toolpath highlighting on g-code program table selection.

Version 0.4 release:

G-code modification with heightmap.

Original file:

Heightmap:

Bicubic interpolation:

Modified file:

Version 0.3 release:

- Recent files & commands lists added.

- Custom Z-probe commands supported now.

- Imperial units of GRBL reports support added.

- Main form compacted.

Visualizer only view:

Table only view:

Live G-code editing:

Version 0.2 release:

- Jog/spindle control with numpad added:

- Feed override function added.

- «Spindle», «Feed», «Jog» groupboxes collapsible now.

- Visualizer works in «Check mode» now.

- Visualizer Z-buffer option added.

- Some bugs fixed.

About

GRBL controller application with G-Code visualizer written in Qt.

Источник

Grbl controller linux deb

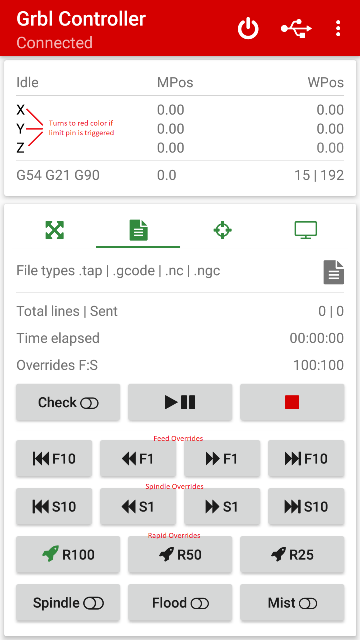

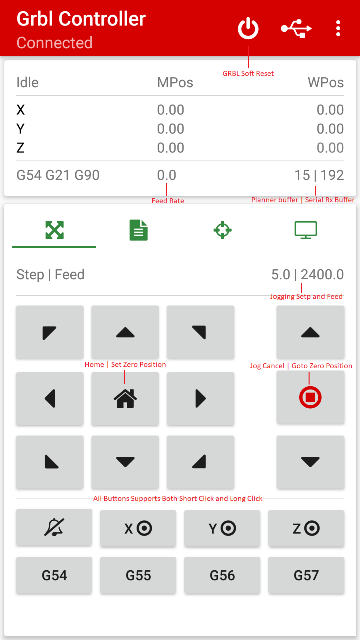

Compact android mobile application for GRBL powered CNC machine.

- Supports both Bluetooth and USB connections

- GRBL 1.1 real time feed, spindle and rapid overrides support.

- Simple and powerful jogging control.

- Uses character counting streaming protocol.

- Real time machine status reporting (Position, feed, spindle speed, buffer state. Buffer status report needs to enabled using the setting $10=2).

- Supports Sending G-Code files directly from mobile phone. (Supported extensions are .gcode, .nc, .ngc and .tap. G-Code files can be placed anywhere in the phone or external storage).

- Supports short text commands.

- Supports Probing (G38.3) with auto adjust Z-Axis.

- Manual tool change with G43.1

- 4 Highly Configurable Custom Buttons which supports multi line commands (Supports both short click and long click).

- Application can work in background mode, by utilizing the less resources, there by consuming less power.

- For android versions Marshmallow or above, use your OS permission manager and grant «Read External Storage» permission in order to get file streaming working.

- G-Code files can be placed anywhere in the phone or external storage, but they must end with one of the following extensions .gcode or .nc or .tap or .ngc.

- If you are connecting Bluetooth module first time to your machine, then make sure you have changed the baud rate of the BT module to 115200. (Default baud rate of the GRBL 1.1v firmware is 115200 as 8-bits, no parity, and 1-stop bit).

- HC-05 Bluetooth module setup http://www.buildlog.net/blog/2017/10/using-the-hc-05-bluetooth-module/

- HC-06 Bluetooth module setup https://github.com/zeevy/grblcontroller/wiki/Bluetooth-Setup-HC-06

- No trimming of decimal places

- Does not remove unsupported Gcodes

- No expansion of Canned Drill cycles or M06 Tool Change

- Some times jog stop button will not work effectively, need to press the jog stop button two times.

Special thanks to

- Will Winder https://github.com/winder/Universal-G-Code-Sender

- Joan Zapata https://github.com/JoanZapata/android-iconify

- Markus Junginger https://github.com/greenrobot/EventBus

- Felipe Herranz https://github.com/felHR85/UsbSerial

- nbsp-team https://github.com/nbsp-team/MaterialFilePicker

- Chuang Guangquan https://github.com/warkiz/IndicatorSeekBar

About

Compact android mobile application for gcode streaming and controlling a cnc machine with grbl firmware

Источник

Grbl controller linux deb

chamnit released this Aug 26, 2019

This release fixes minor bugs and includes a new optional dual motor support for self-squaring gantry homing.

[OPTIONAL] Dual motor support for self-squaring gantry homing.

NOTE: Default build remains the same! Dual motor support can only be enabled in config.h.

New dual motor support feature for gantry CNC machines. An axis motor is efficiently mirrored to a dedicated set of step and direction pins (D12/D13 or A3/A4) with no detectable loss of performance. Primarily used to independently home both sides of a dual-motor gantry with a pair of limit switches (second shared with Z-axis limit pin). When the limit switches are setup correctly, Grbl will self-square the gantry (and stay square if $1=255 is programmed). Beware use at your own risk! Grbl is not responsible for any damage to any machines.

Dual axis motors is only supported on the X-axis or Y-axis. And deletes the spindle direction(D13) and optional coolant mist (A4) features to make room for the dual motor step and direction pins.

Dual axis homing will automatically abort homing if one limit switch triggers and travels more than 5% (default) of the non-dual axis max travel setting. For example, if the X-axis has dual motors and one X-axis triggers during homing, Grbl will abort 5% of the Y-axis max travel and the other X-axis limit fails to trigger. This will help keep any misconfigurations or failed limit switches from damaging the machine, but not completely eliminate this risk. Please take all precautions and test thouroughly before using this.

Dual axis motors supports two configurations:

Support for Arduino CNC shield clones. For these, step/dir on pins D12/D13, and spindle enable is moved to A3 (old coolant enable), while coolant enable is moved to A4 (SDA pin). Variable spindle/laser mode option is NOT supported for this shield.

Support for Protoneer CNC Shield v3.51. Step/dir on pins A3/A4, and coolant enable is moved to D13 (old spindle direction pin). Variable spindle/laser mode option IS supported for this shield.

[new] Altered the way default settings are stored and restored. Saved about 300 bytes(!) of flashed size. Should free up enough for certain configurations of CoreXY machines.

[fix] Added a build info feedback mechanism for enabling the safety door input pin.

[fix] Correct control pin state checking within pin change interrupt. Improper if-else statements could lead to missed signal.

[fix] If statement bug fix related to jog motion modal group error checking.

[fix] Spindle/coolant rare bug fixes.

[fix] When the optional M7 mist coolant IO was enabled, coolant overrides was not disabling correctly.

[fix] Coolant override states was not restored correctly after a parking motion in certain situations. It would restore programmed state, rather than current overridden state.

[fix] Now allow coolant overrides to operate during jogging motion.

[fix] Invert control pin mask typo.

[fix] Fix apparent error in restore masking that causes the call to coolant_set_state to not re-enable the mist (M7) output if it was previously enabled.

[update] Added Bob’s CNC E3 and E4 CNC machine defaults.

[update] Updated instructions in fit_nonlinear_spindle.py. Repl.it has changed since the last time fit_nonlinear_spindle.py was tested.

chamnit released this Jul 18, 2017

This release includes a critical bug fix (rare) and some other minor bug fixes, updates and new non-critical features.

[fix] A very rare bug would cause Grbl to crash in a very special and very rare set of circumstances. It would occur only when actively lowering feed/rapid overrides and the programmed move and settings aligned perfectly. Re-factored the problem code to eliminate the potential issue.

[new] A nonlinear spindle speed/PWM output option via a piecewise linear fit model. Enabled through config.h and solved by a Python script in /doc/script.

[new] fit_nonlinear_spindle.py. A solver script that can be run on http://repl.it for free. No Python install necessary. All instructions are available in the script file comments.

[new] stream.py has been updated to include status reports feedback at 1 second interval.

[new] The stream.py streaming script now has a check-mode option, where it will place Grbl in $C check mode automatically and then stream the g-code program. It’s a very fast way to check if the g-code program has any errors.

[fix] stream.py bug fix with verbose mode disabled.

[fix] When in M3 constant laser power mode, a change from G0 to G1 would not set the laser on, if G1 was passed with a coincident target. Motion controller now checks for a coincident target situation and will force a spindle sync when detected.

[fix] Restrict M3 forced updates when there is a motion block with a coincident target. Force syncing of the spindle state can lead to some pauses during a job that has coincident targets. That’s not particularly desirable. This ensures M4 dynamic mode is not effected by this force-sync.

[fix] The build info options of “two switches on an axis” and “homing init lock” shared the same letter ‘L’. The former is now ’T’.

[fix] When M7 and M8 are both enabled, $G report would show M78 , rather than M7 M8 . This only effects systems that enable M7 mist coolant in config.h. Not the default build.

[fix] When trying to enable laser mode with $32=1 and VARIABLE_SPINDLE is disabled, the error code shown was improperly stating it was a homing failure. Added an new error code specifically for the laser mode being disabled without VARIABLE_SPINDLE.

[fix] The debug variable was not initialized if the debug option was enabled in config.h

[fix] Updated error_codes CSV file to the same format as the others.

[update] Added PocketNC FR4 defaults. Needs some additional work though to be compatible.

Источник