- How to install plastic window with their hands?

- How to install plastic around windows of a brick house?

- 2 Answers

- Trending Questions

- Trending Questions

- Answer Questions

- Answer Questions

- With Your Hands — How To Make Yourself

- How to do something yourself, with your own hands — home master’s site

- Installation of a plastic window with your own hands — measurements, consistency and correct installation

- How to properly install a plastic window in the opening

- How to properly measure the window opening

- Fastening and installation of windows by own hands

- Dowels for fastening frames

- Screws for windows

- Anchor plate for fixing the frame

- Anchor fastening of the window

- After installing and fixing the window with your own hands, you need:

- Do-it-yourself plastic window installation — photos and drawings for the article

How to install plastic window with their hands?

Windows, plastic is instantly attracted consumers immediately after its release on the market. Currently, almost nobody sets their classic wooden counterparts. Their advantage is in the fact that installing them may not only a professional with experience. After reading this article you will learn how to properly install a plastic window. So, let’s start.

With the installation of double-glazed Windows features the following details:

- You can install them even in winter. However, you yourself should understand that it is best to work in warm time of the year. In addition, summer and spring mounting foam hardens better. So how to install plastic window You need all the instructions, this process may take more than one day to live in a windswept apartment is not too comfortable.

- The Need for accurate measurements of window openings. The success of the measurements depends on the success of the event.

If you want to install plastic Windows cheaply (yourself) in the panel house, you should also measure the internal opening. The fact that in such cases the box with the frames rests on the opening section which resembles the letter “G”. The measurements were carried out in the following steps:

- Measure the distance between the side jambs;

- Measure the distance from the sill to slope both sides;

- Note that the width of the sill should be equal to the width of the wall, excluding the width of the profile.

It is believed that the easiest way to install double-glazed Windows in a wooden house, but it is not. Note that the tree – the material is capricious, easily expands and contracts under the influence of environmental factors. So to install Windows you need to okoshechka. It is independent design of timber similar to the trim of the door frame. Thanks to her, the window is not jammed and does not deform due to the «movements» of the tree.

Despite the fact that the method of seedling in vegetable production is a very time consuming process, it is used by most gardeners. Planting seeds in open ground is an easy and convenient method, but it is effective only in certain climatic zones. I.

When the vehicle began to fill the road, their popularity began to gain reflective paint. Thanks to this paint, as drivers and pedestrians becomes much easier to avoid accidents in the dark. Purpose paint Reflective paint – paint material, whic.

In Soviet times, many collecting badges, emblems, pennants. To get them was not easy. And today, thanks to technology, you can make them yourself. Knowing how to make icon with your own hands, and you can make original gifts to your friends, and make.

Once again: > so how to install plastic window is quite difficult, you must carefully follow the instructions.

- Pulling the plugs, get yourself a glass.

- To Mark each of them so as not to confuse with the installation.

- Remove the protective film from the ends, glued in its place a paper tape or a similar coating.

- At the end of the plastic frame glued vapor barrier tape.

- By Setting the opening the bearing pads, put them in the assembled window.

- Carefully adjust it, using the building level.

- Finally lock the box by means of metal profiles and to fill the void of quality foam.

- Set the window-sill, sills, and then carry out the installation of double-glazed Windows. Attach the plug you need to start from the top.

- Install the inner slopes, and to attach decorative profile.

If you’re going to comply with all our instructions to install plastic Windows (Moscow their range will amaze anyone) can quickly and efficiently. Wish you success!

How to install plastic around windows of a brick house?

We live in an old, very poorly insulated house, and it’s very drafty/cold during the winter. We’ve tried two-sided insulating tape that you put in the window sills, caulk strips that you put around the frame, etc. and none of it works. Is it worth the money to buy the plastic that you can put over the outside of your windows? The draft seems to be coming from where the window itself meets the sill, but also around the perimeter of the window (where the edging/molding is attached to the wall). I’ve read a few articles online about «how to» install plastic, but they all say that the plastic comes in kits and you need to attach it with the included double sided tape to your wooden window frame. our house is brick and there’s not much of a frame outside. What little wood there is has been painted over many times, and I doubt tape would stick to it. Should I try to do it anyway? Is it worth the cost?

2 Answers

You can caulk around the windows first. That should have been done at instalation. If you need to, you can use 100% silicone to adhear the plastic to plastic and it is easily removed in the spring. Do a test section and let it cure for 48 hours and see how it holds and removes. I never did it but I do alot of caulking. If you dont seal the draft, no matter what you do, it will eventually blow off.

Carefully remove the decorative molding from around the window.(inside)

Then either stuff fiberglass insulation in the crack between the window and the jam.

Or use the foam insulation in the can.

Then replace the molding.

A lot of people put plastic on their windows using staples

Trending Questions

Trending Questions

Answer Questions

Answer Questions

Yahoo Answers is shutting down on May 4th, 2021 (Eastern Time) and the Yahoo Answers website is now in read-only mode. There will be no changes to other Yahoo properties or services, or your Yahoo account. You can find more information about the Yahoo Answers shutdown and how to download your data on this help page.

With Your Hands — How To Make Yourself

How to do something yourself, with your own hands — home master’s site

Installation of a plastic window with your own hands — measurements, consistency and correct installation

How to properly install a plastic window in the opening

Those who watched the work of masters installing a plastic window saw the order of work that occurs in this process.

The entire installation of the insulating glass unit is as follows.

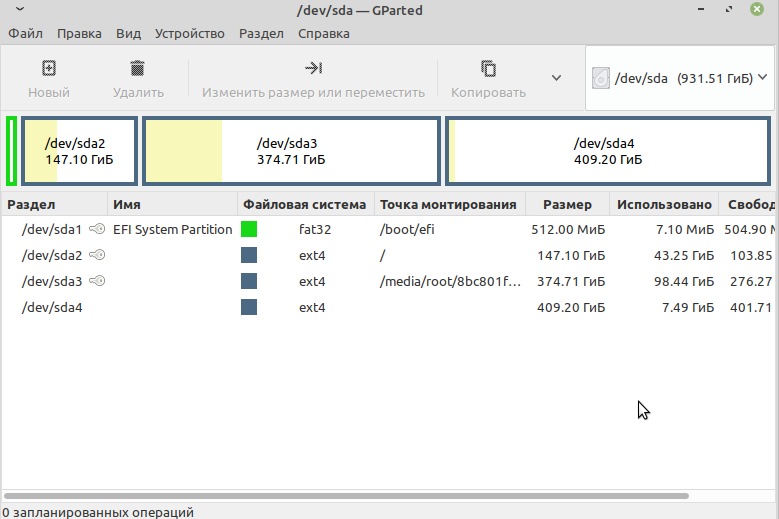

The unit of the double-glazed unit is installed in aperture prepared beforehand and cleaned from the remains of the previous window. Then it is vertically and horizontally adjusted with the help of a level, fixed with spacers (someone uses plastic, someone’s tree). Stage fastening of the window to the wall is to fix the block with anchor plates or dowels.

In the resultant of this simple process, the gaps between the future window and the walls of the escarpment are inserted by spacers and filled with mounting foam (the spacers will not allow the foam to change the correct geometry of the window so that it does not lose its shape and as a consequence, subsequent normal operation with the opening / closing cycle) . After solidifying the polyurethane foam, it and the spacer are cut to the level with the frame of the block and the inner and outer window sill is fixed. After this, the final finish is made — the cracks formed by the installation are sealed with silicone and the slopes are trimmed.

Such installation is fast, cheap and customary for many and observing the simplest tips for caring for plastic windows their service life can be quite long.

However, after this period, from the owners of windows installed in this simplest way, complaints begin to come about that the doors are not closed properly, the plaster is showered, and moisture appears on the slopes or they are even covered with frost. Windowsills made of laminated chipboard are swollen, the seams sealed by silicone diverge, a smell of mold emanates from the window, and she herself also starts to gather in the corners.

The situation is different with the installation of a finished product. On the construction site, due to well-known reasons for the installer, a wide field of «creativity» opens and, as a consequence, the opportunity to make mistakes that can later lead to the malfunctioning of windows, and hence to problems.

In this article, we propose to draw your attention to some of the key points outlined in the handbook for the installation of window structures, which was released by one of the leading manufacturers of window profiles.

How to properly measure the window opening

In our opinion, the practice of those who adhere to the principle: «who measured, he also mounts.» As the theater begins with a hanger, and the installation of windows begins with a correctly conducted measurement of the window opening.

For this, the window opening is measured in height (left, middle and right) and width (top, middle and bottom). The smallest size is the determining factor in the manufacture of the window. Using a telescopic wooden scale scale and the spirit level, check whether the slope is laid at a right angle. (Currently, if conditions permit, you can use the appropriate laser instruments — range finders (more about the selection of range finders and what it is can read here)

There is another opportunity to check the angle. For this, both slope diagonals are measured and compared with each other. If these values differ from each other, about the angle in 90 ° out of the question. In this case, a plumb line comes to the rescue. If the slope deviations exceed the allowable limit deviations (see Table 1), the opening can not be accepted for the installation of window structures.

| Table 1. Limit deviation of dimensions | ||

| Nominal size of the opening, m | Before 3 | from 3 to 6 |

| Window, doorways, recessed elements | ± 12 mm | ± 16 mm |

| The same openings, only with ready slope surfaces | ± 10 mm | ± 12 mm |

In the event that excess tolerance or deviation from a given building situation entails any changes or additions, all this must be agreed before working with the owner (in the event that you do not insert the window yourself and yourself). Particular attention should be paid to whether the minimum width of the joints is provided along the entire perimeter (see Table 2).

| Table 2. Minimum width of assembly seams | ||||

| Length of the structural element, m | 1,5 | 2,5 | 3,5 | 4,5 |

| PVC (white), mm | 10 | 15 | 20 | 25 |

| PVC (colored or decorated for wood), mm | 15 | 20 | 25 | 30 |

When using pre-compressed sealing tape, the minimum joint width is 8-10 mm.

When designing windows and doors, all dimensions are oriented toward the “clean” dimensions of the building (without decoration). For compliance with these dimensions and marking meter risks should be responsible construction firm. The risk is applied in all rooms in the immediate vicinity of windows and doors. A meter of risk is necessary, first of all, in order to precisely design the window sill and the lower part of the window immediately adjacent to it or to correctly determine the position of the door threshold. This is important both from an aesthetic point of view — that visually all the windows are at the same height from the floor, and from a purely practical one — as a rule, heating devices are placed under the windows.

In practice, the height of the window sill often does not correspond to the design, and therefore it is very important to remove or, conversely, to report a number of bricks at the measurement stage.

It is not superfluous to recall the need for glazing the building to monitor the severity of the facade lines. It may happen that the window opening, although it is permissible in size, can not be accepted for mounting windows, since it is sufficiently offset from the axis. When designing and installing windows, it is necessary to make sure that the imposts or the joint are always on the same axis. To do this, using a plumb line attached to the upper floor of the building, vertical axial risks are applied on the window sill.

It should be remembered that windows in most cases are projected from the bottom up and from the center to the right and to the left. The final step in coordinating the position of the window in the opening is to apply a horizontal façade mark. This is especially important when the building is glazed with tinted glass. You, for certain, paid attention to how unprepossessing some buildings look, while expensive mirror glass is used for their decoration. This is due to the fact that the installation of the windows did not comply with the plane of the facade. For tinted, and even more so, mirror glass, deviations of only a few degrees are enough to get an absolutely unpredictable external effect. And who can vouch for the accuracy of the installation of walls and their thickness? To paint the horizontal facade marks, two plumb bobs are used, posted on both sides of the building facade, and a thread stretched between them on each floor. Risks are placed on both vertical slopes of each opening.

And only after the window openings are coordinated in all three planes and brought into line with the project, should final measurements be taken. Truly, «measure seven times — cut once.»

When measuring it is important to check the condition of the plaster for the absence of cavities in it, as well as its strength. Pay attention to the classes of plaster and mortar. Gypsum plaster and similar materials can not be used from the outside.

After all the measurements of the opening are completed, it remains to determine the position of the installation plane of the window in the opening. To assess the connection points, in terms of building physics, it is necessary to know the temperature in various elements of the building structure. However, if you do not go into the details of heat engineering calculations, you can argue that to ensure reliable heat protection in single-layer exterior walls, one should strive to mount windows with their location in the middle of the thickness of the window opening.

Fastening and installation of windows by own hands

Windows should be securely fixed in the building structure, so as not to pose a potential hazard to human life and health. This rule is unconditional and absolute. No reason for economic expediency can be taken into account if they cause doubts about the safety of the structure. Mounting should systematically and reliably transfer to the construction structure all the loads acting on the window taking into account the possible displacement and movement of the window and its elements. At the same time, the fastening must reliably distribute and smooth the loads.

A detailed description of solving the problems of window statics is beyond the scope of this article.

However, those who are engaged in the installation of window structures, it should be remembered that for walls with window openings of an area of more than 9 m 2 and lateral length more than 200 cm with a translucent structure consisting of frames, posts and crossbars with glazing, it is necessary to calculate the static strength (with the help of specialized design organizations).

After all, the task of window statics is to prove that all the forces — wind, snow, dynamic loads, loads from the dead weight of the structure and crowds (flights of stairs, schools, sports facilities), etc. — transmitted only to the supporting structures of the building.

The use of double-glazed windows imposes additional restrictions on the deflection for crossbars and racks. As a rule, the permissible deflection established by the manufacturer of insulating glass units should not exceed 0,8 mm. The fastening points of the window units must be determined in such a way that the perfect transfer of the resulting loads to the construction structure is guaranteed. The fixing intervals must match the dimensions shown in figure 1 and 2.

In special cases, additional fixing may be necessary.

Compliance with these intervals prevents the deformation of the frames resulting from overvoltage, which in extreme situations can lead to cracks.

When installing anti-burglary windows, it is necessary to install strong gaskets between the frame and the construction structure in the fastening points.

If dowels, anchor plates, etc., perceive a load acting in a direction perpendicular to the plane of the window, then the forces that act on the window in its plane must be routed to the building structure through the bearing pads. It should be remembered that the pads can only take the load from the pressure. It is necessary to pay attention to their sufficient compressive strength and the need for the correct arrangement of the pads in the places of the corners of the frames and the attachment of the imposts. As carrier pads, you can use, for example, special sets of plastic glazing laths or wedges made of solid wood.

Wedges, which are used for mounting as an auxiliary fixture for installing a window in the installation plane in horizontal and vertical positions, must necessarily be removed after the fastening is completed. The pad must be flat as long as it is required to transfer the resulting loads to the building structure. The presence of unnecessary spacers not only does not improve the situation, but can lead to additional loads acting on the window structure.

Bearing and spacer shoes should be installed so that they do not interfere with the thermal expansion of the profiles.

When integrating and fixing the window in the opening, special attention should be paid to whether the minimum width of the joints is ensured. To determine the minimum allowable width of joints, the following values of the temperature change in the length of the profiles can be used:

- PVC white-1,6mm / m;

- Color PVC — 2,4 mm / m.

Above, in the table 2, the values of the minimum width of the joints are given. In the case of non-observance of the minimum width of the installation joints along the perimeter, installation can not be started.

The choice of the kind of dowels, screws, linings and anchors used for fastening the window depends on the type of masonry of the building structure. It is possible to use special dowels for hollow blocks or aerated concrete. All fasteners must be resistant to corrosion. In wet rooms (indoor swimming pools, saunas, etc.) it is necessary to use stainless steel parts.

When choosing the dimensions of fasteners, you should take into account the own weight of the window unit, the weight of additional elements and additional loads such as wind loads, loads from the crowd (the weight of people who can grab the window in a critical situation), loads from shocks during opening and closing and etc.

Explanation: in figure 3 and 4, 1 denotes a carrier pad, and 2 with a spacer

Dowels for fastening frames

The advantage of a dowel for fastening frames is that the frame can slide freely over the sleeve. This allows the frame to expand freely. Especially well-proven metal dowels with sleeves with a diameter of 8 and 10 mm. The dowels perceive loads on shear, shear or bending. Therefore, when they are used, especially with heavy weights, restrictions are imposed on the distance between the wall and the frame. It is necessary to pay attention to the appropriate choice of dimensions according to the supplier’s instructions.

The dowels are designed to secure the window block to concrete walls, brick walls, aerated concrete, natural stone, pumice stones, etc.

If dowels are used in the lower horizontal part of the frame, they must be especially well sealed in the fold of glass. Otherwise, defects from penetration of water will appear in the frame. The minimum diving depth of the dowel in the wall is 30 mm (Figure 5).

Screws for windows

Mounting the frame to the clutch self-tapping screws is made directly, without dowels. Fastening is carried out in the same way as conventional dowels, the only difference is that there is no need to drill large holes. Screws take the same load as the dowels.

Self-tapping screws are designed to attach frames to concrete walls, full bricks or full silicate bricks, as well as bricks with voids (minimum through 2 partitions), pumice and wood, etc.

If the screws are used in the lower, horizontal, part of the frame, they must be especially well sealed in the rebate of the glass. Otherwise, the frame will have defects from penetration of water. The minimum depth of immersion of screws in the wall 30-60 mm (Figure 6).

Anchor plate for fixing the frame

Anchor plate (Fig. 7) is a relatively flexible element and does not interfere with the thermal expansion of the profile of the frame. The anchor plate can only absorb forces directed perpendicular to the plane of the window.

Anchor plate should be used where the distance between the anchor for fixing the frame and the edge of the masonry is not enough or the sealing of the dowel in the rebate of the glass (only from the bottom) is not guaranteed. Such a plate is a profile-oriented element. In principle, the common feature of the anchor plates of different manufacturers is that the mounting shelf is mounted on a fixing base with the ability to rotate and can thus be used in any mounting situation.

As a rule, in such a plate there are several elongated and several round holes for fixing in the desired position.

Such a plate is inserted at one angle at the back of the frame with one foot and pressed against the frame until the second foot is securely fixed. In addition, the base of the anchor plate is attached to the frame using a self-tapping window screw. If necessary, the anchor plate can be bent to give it some form or another. Anchor plate is fastened by means of appropriate screws and dowels to the construction structure.

Anchor fastening of the window

Anchoring fasteners, such as steel channels, corners, pipes, etc., are capable of absorbing large loads. They are used in facade structures and other heavy loads. When using an anchorage, in each specific case it is necessary to calculate the static and dynamic loads perceived by it, it is mandatory.

The basic rules that must be adhered to when attaching window frames:

- The fixing must only be mechanical. The use of foams, adhesives and similar means for securing windows is unacceptable.

- It is necessary to make the correct drilling, i.e. without the impact mechanism (with the exception of concrete). The drill should be chosen more truly, as it is possible to damage the frame by the chuck of the drill. If possible, use a PVC sheath to protect the edges. Drilled holes must be blown. With bricks with vertical voids, drilling in the seam joints is necessary.

- Pay attention to the bearing capacity and length of the dowels.

- It is necessary to follow the dowels specified by the supplier of inter-axis and edge distances in accordance with the building material.

- Screws must be wrapped evenly, without insertion into the frame, for this purpose a screwdriver with a torque limiter should be used.

- Clogging nails, even a special version is not recommended, since it is impossible to control the depth of their approach.

After installing and fixing the window with your own hands, you need:

- to check the correctness of the installation of the window horizontally, vertically and axially;

- remove leveling and fixing wedges. The wooden wedges that were used to reconcile the window are not load-bearing pads and should be removed after attaching the window;

- Clean the grooves from the chips after drilling and, if necessary, adjust;

- to conduct operational inspection of windows.

Do-it-yourself plastic window installation — photos and drawings for the article

© Copyright. Ryzhankov candidate so-called.